According to poll results conducted by Food Engineering, 71% of food processors in North America believe that gross throughput for their facility will increase 14% in 2015. In order to achieve this increased throughput, the Food & Beverage Industry is looking at advancements through automation, food safety and sanitary design.

Through automation, manufacturers have been able to increase productivity. Robotic technology has furthered integration by providing flexibility which has allowed manufacturer’s to reduce costs, improve quality and expand capacity within their facilities.

At NSK, we understand the operating conditions machinery must withstand in order to achieve long operating life in highly corrosive environments.

- Advanced Technology

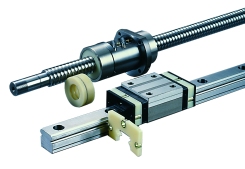

NSK is driven by technology and provides standard stock of linear guides, ball screws and linear actuators to meet the needs of the Food & Beverage industry.

- Interchangeable rails and sliders can be combined in several different configurations to accommodate manufacturer’s linear motion requirements. Choose from standard stock of new NH/NS Series or PU/PE miniature Series.

- X1 Seal technology for ball screws features a double seal structure that not only offers superior dust resistance but also grease retention.

- MCM Series combines NSK ball screws, linear guides and support bearings into one compact unit. All accessories including sensor units, rails, covers and combining brackets can be purchased through NSK to offer a solution which will save design and installation time.

- FDA Compliant

NSK has developed an FDA compliant K1™ Lubrication Unit that is ideal for environments where grease replenishment is undesirable or where grease is easily washed away. This patented technology is guaranteed to provide maintenance-free operation for up to 10,000 km or 5 years. Longer results can be achieved based on specific applications. This solution is available on all standard NSK products including linear guides, ball screws, Monocarrier™ and Toughcarrier™ linear actuators and Robot Modules™.

- Anti-Rust Material

Standard rail and ball screw shafts use premium steel material. But for Food & Beverage applications, we manufacture special coatings including stainless steel, Armoloy™ and low temperature fluoride coating. Likewise NSK’s product line of Monocarrier™ and Toughcarrier™ actuators come standard with rust-resistant, low temperature chrome plating offering superior rust protection.

To find out more about NSK product solutions for Food & Beverage, visit our website or contact your local NSK representative. Follow us on Linked-In, Facebook, and Twitter to stay updated on all the latest related to Food & Beverage industry and other industries that utilize NSK products.

Source: “The State of Food Manufacturing: It’s all about throughput” Food Engineering

You must be logged in to post a comment.